News

- Production technology...

- How to analyze the same ...

- Introduction to conical ...

- The advantages of twin...

- The characteristics and ...

- Characteristics of...

- Characteristics of...

Hot Product

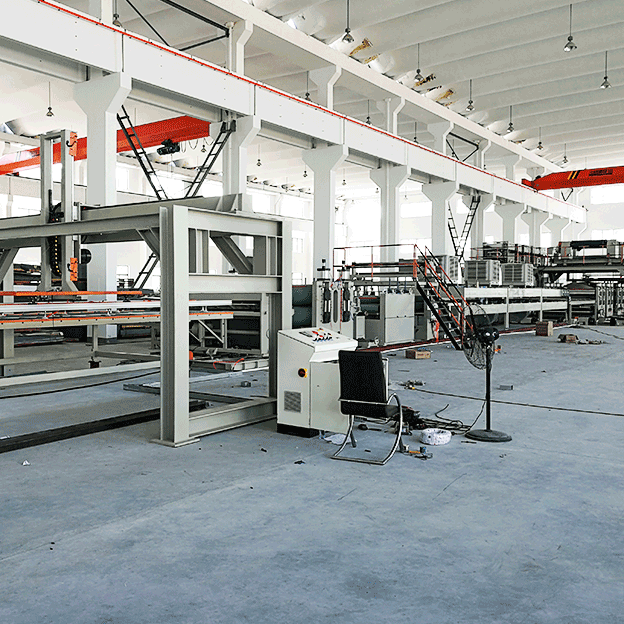

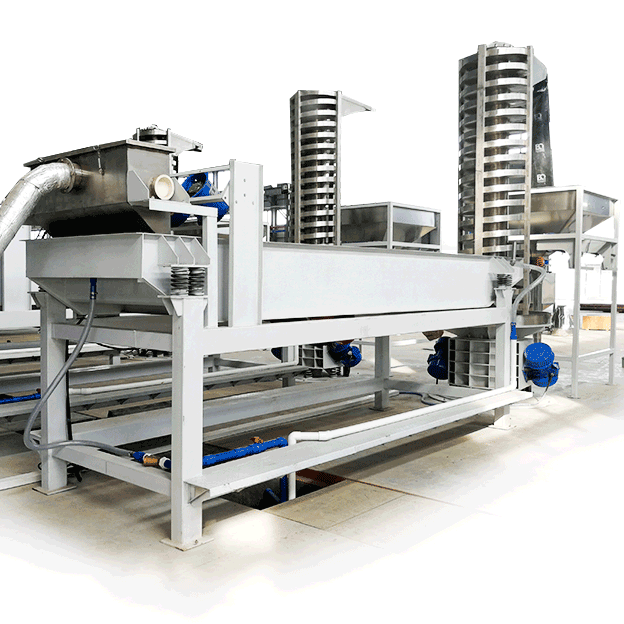

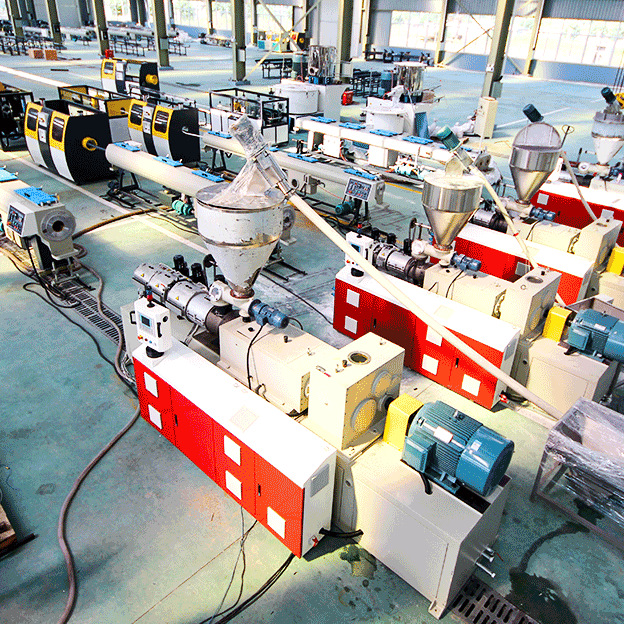

PP/PE/PVC line

The company developed the same conical twin-screw double-wall corrugated pipe extruder to overcome their own shortcomings, with high yield, low energy consumption, mixing and dispersing effect and good plasticity, low shear, can add high proportion of calcium carbonate and Recycling materials and many other innovative advantages.

- Product Details

-

For the special cone double extruder feed large but easy to break the screw; single screw extruder stable but the energy consumption, low yield and other aspects of the company developed the same tapered twin-screw double-wall corrugated pipe extrusion In the case of retaining the advantages of the conical twin-screw extruder and the single-screw extruder, they overcome their shortcomings, have high yield, low energy consumption, kneading dispersion effect and good plasticity and low Cut, can add a high proportion of calcium carbonate and recycled materials and many other innovative advantages. The use of customer feedback information, the product than similar products more than 30% energy saving, you can completely replace the single screw host, is the ideal choice for the current double wall bellows host.

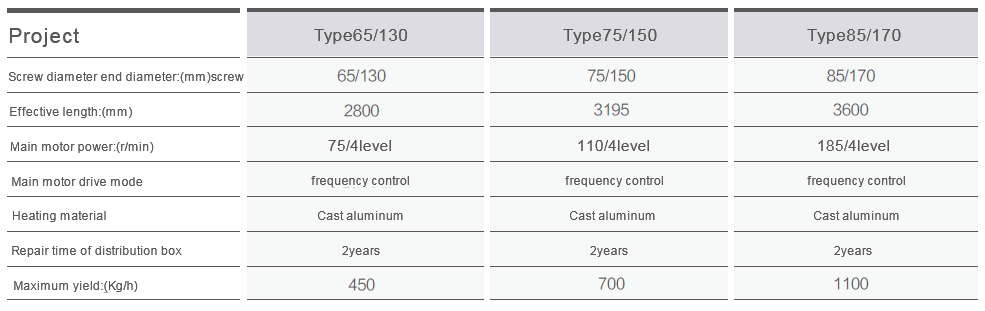

Specifications